Let’s Be Honest: It’s Tough Out There

If you’re in the business of moving cement, steel, tiles, or timber, you already know the stakes are high. Delays aren’t just inconvenient; they can stall entire construction sites. Errors in orders, stock mismatches, late deliveries, or frustrated dealers? They all cost you time, money, and reputation.

And here’s the real kicker: many building material distributors are still losing money daily, not because of competition or lack of demand, but because their operations aren’t keeping up.

The good news? There’s a smarter way forward. And that’s exactly what we’re talking about today.

5 Ways Money Slips Through the Cracks in Distribution

Even businesses with high sales volumes and loyal customers can struggle with silent profit leaks. Let’s break down the most common ones.

1. Inventory Confusion

When you don’t have real-time visibility into your stock, especially across multiple warehouses, it’s easy to:

- Overstock products that don’t move

- Understock fast-selling items

- Lose track of damaged or misplaced materials

Every mismatch leads to lost sales or wasted money tied up in excess inventory.

2. Delivery Inefficiencies

Delivering bulky materials to scattered or remote sites is a logistical challenge. But without optimized route planning and vehicle tracking, you end up with:

- Wasted fuel

- Unused truck space

- Missed deadlines

One late delivery might not seem like much, but for your customer, it could delay an entire project. And they remember that.

3. Manual Order and Billing Errors

Still managing orders through calls, WhatsApp, or paper slips? That’s risky business.

- Wrong product dispatched

- Incorrect pricing

- Delayed or missing invoices

Manual processes may feel familiar, but they’re prone to human error, and they don’t scale well.

4. Missed Sales Opportunities

If your team doesn’t have access to real-time data, like which products are trending, what’s running low, or which dealers are slowing down, you’ll struggle to:

- Forecast demand

- Upsell efficiently

- Optimize promotions

Data isn’t just helpful; it’s essential to stay one step ahead of the market.

5. Disconnected Teams

Sales, warehouse, dispatch, accounts, dealers; everyone needs to be on the same page. But often, they’re not. The result?

- Repeated follow-ups

- Miscommunication

- Delayed decision-making

When operations aren’t synced, friction builds, and that affects your bottom line.

What Smarter Distributors Are Doing Differently

Here’s what the most forward-thinking distributors have figured out: you don’t need to work harder, you need to work smarter.

They’re using systems that connect their people, processes, and data in real time.

Let’s see how that plays out.

# Live Inventory That Makes Sense

Real-time inventory tracking across all depots means:

- No more guessing stock levels

- Quicker order fulfillment

- Lower holding costs

You can act with confidence instead of reacting to surprises.

# Orders That Flow Seamlessly

With the right system in place, orders move from placement to dispatch automatically:

- Stock gets checked instantly

- The invoice is generated on the spot

- The order is assigned to the right delivery route

No bottlenecks. No paperwork. No room for error.

# Deliveries That Just Work

Using smart route planning and GPS tracking, deliveries become more efficient:

- Fewer empty miles

- Accurate ETAs for job sites

- Lower fuel and manpower costs

Your customers start seeing you not just as a supplier, but as a reliable partner.

# Field and Dealer Teams That Sell Faster

Imagine your sales team and dealers being able to:

- Place and track orders from their phone

- See real-time stock and pricing

- View running schemes and discounts

You cut the red tape and close deals faster.

# Decisions Driven by Data, Not Guesswork

With dashboards showing real-time data, you can:

- Track sales by product, region, or rep

- Monitor delivery performance

- Spot slow-moving stock early

No more waiting for monthly reports. You’re always a step ahead.

When Is It Time to Make a Change?

Honestly, you probably already know.

If you’re noticing:

- More customer complaints

- Frequent stock errors

- Long hours spent sorting out miscommunication

- Deliveries running late

- Teams struggling with outdated tools

It’s not just a rough patch. It’s a sign that your current setup is holding you back.

What a Distribution Management System Does

Let’s keep it simple. A distribution management system helps you manage the entire flow, from receiving an order to delivering the material, using a single, connected platform.

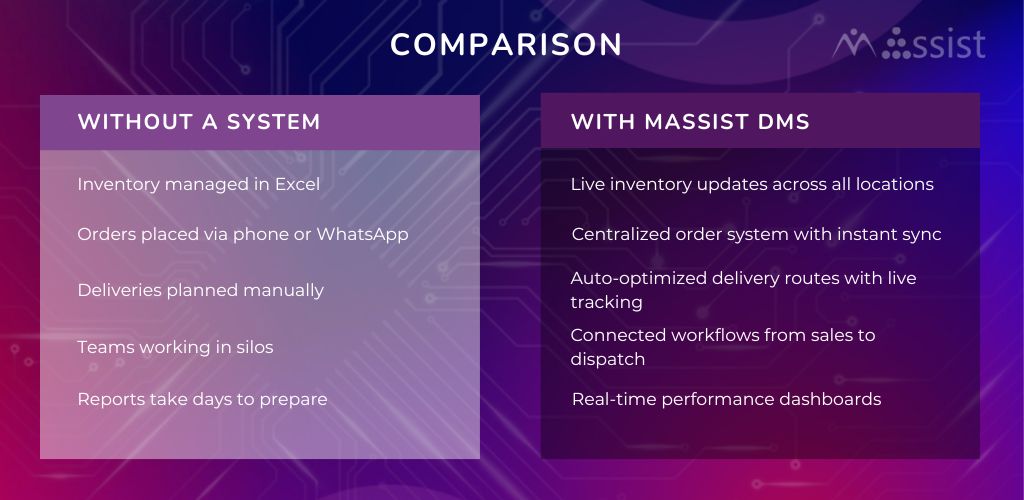

Here’s a quick comparison:

With a good distribution management system, you don’t just track your operations; you control them.

Let’s Be Clear: You Can’t Afford to Keep Leaking Margin

Margins in the building materials sector are tighter than ever. With rising fuel costs, labor shortages, and increasing customer expectations, every small delay or error becomes a big deal.

If your competitors are investing in smarter tools, and you’re still relying on outdated methods, it’s not a fair fight.

This isn’t about software – it’s about survival.

MAssist: Built for the Way You Work

At MAssist, we understand the real-world challenges of building material distribution. That’s why we’ve built a platform that’s tailored to:

- Heavy-load logistics

- Multi-location inventory

- Dealer engagement

- Field mobility

- Real-time business insights

We don’t just sell software. We help you take back control.